CANTEACH Selected Images.......

Back

Page

1 2

Next Page

Click on the small images to see an enlarged view.

|

File info: source/00.jpg (size: 127 K)

Description: John M. Dyke B.A.Sc., P.Eng

John was involved in steam generator design for 35 years, from 1945 to 1980. He lead the design team for the Pickering A nuclear station in the mid 1960s. They were the first with internal economizer and integral steam drums. The 48 steam generators at this four-reactor station have had exemplary performance. He is a registered professional engineer with the province of Ontario. He has been honored by the American Society of Mechanical Engineering as a life member for outstanding lifetime achievement. The Canadian Nuclear Association also honored him with their Outstanding Contribution Award for designing the steam generators used in CANDU stations.

Source: [DYKE2005] Unless otherwise noted, the images herein were contributed by John Dyke from his personal collection of drawings. Contributed to CANTEACH April, 2005.

|

|

File info: source/00b.jpg (size: 141 K)

Description: John obtained his B.A.Sc. in Mechanical Engineering from the University of Toronto in 1943 and joined the Royal Canadian Navy Volunteer Reserve as an Engineering Officer posted with the Royal Navy doing convoy duty in the Mediterranean. When he returned to Canada he worked at the Naval Research Establishment in Halifax developing anti-acoustic torpedo gear. Coincidentally, these were parallel rods that vibrated in water streams. After the war John did steam boiler engineering at several firms and became Chief Engineer of Dominion Bridge's new boiler department in 1958. Here he attended a special course on nuclear design and submitted bids for early nuclear steam generators and reheaters. In 1964 he joined Babcock and Wilcox Canada, first as a project engineer on fossil-fired boilers and then to head up the new nuclear steam generating section where they developed a new 500 MWe design for Pickering A.

Source: [DYKE2005]

|

|

File info: source/01.jpg (size: 364 K)

Description: The US Navy nuclear submarine, a good bed fellow to the CANDU

Source: [DYKE2005]

|

|

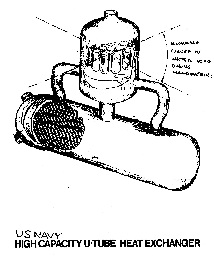

File info: source/03.jpg (size: 593 K)

Description: The improved design of the vertical steam drum was partially financed by BW Canada. As a result, the CANDU boiler has the best and latest design.

Source: [DYKE2005]

|

|

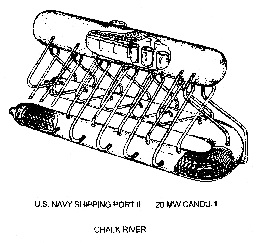

File info: source/06.jpg (size: 622 K)

Description: The scaled down US Navy boiler for the 20 MW NPD plant. Image issued after the 45 year security period after WW II.

Source: Unknown.

|

|

File info: source/07.jpg (size: 558 K)

Description: A stylized sketch of the 20 MW nuclear submarine boiler for NPD. Image issued before the end of the 45 year security period after WW II.

Source: [DYKE2005]

|

|

File info: source/08.jpg (size: 433 K)

Description: A sketch of the NPD heat exchanger. This sketch is a study of the flow that might have caused the first fretting failure in Canada.

Source: [DYKE2005]

|

|

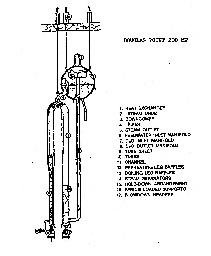

File info: source/09.jpg (size: 259 K)

Description: AECL design of the 200 MW Douglas Point Boilers with horizontal steam drum and vertical hair pins heat exchangers. "The evidence shows that the method of tube support design is critical if tube failures are to be avoided. The mechanism of failure of inconel is not yet fully established but local boiling to dryness initiates the attack. It can be shown that drilled support plates with parallel sides and small clearances around the tube can promote adverse conditions. The lattice bar type tube supports with line contact on the tubes and large open areas have proven to be successful and no failures are reported either from dryout or vibration." [ref DYKE1970]

Source: [AECL]

|

|

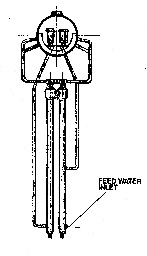

File info: source/11.jpg (size: 169 K)

Description: CE simplified design arrangement of the AECL preferred design for Douglas Point.

Source: [DYKE2005]

|

|

File info: source/15.jpg (size: 532 K)

Description: Pickering A - the first boiler in North America with design features that showed that a nuclear recirculating steam generstor (RSG) could be designed to survive its hostile environment.

Source: [DYKE2005]

|

|

File info: source/16.jpg (size: 586 K)

Description: Combustion Engineering design of a RSG for the NA market.

Source: [DYKE2005]

|

|

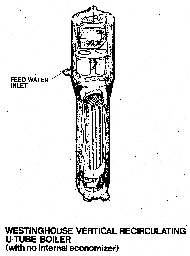

File info: source/18.jpg (size: 511 K)

Description: Westinghouse design of a RSG for the NA market. The drilled hole tube support plate with associated steam bypass holes was a very poor design and most, if not all, SG's had to be taken out of service.

Source: [DYKE2005]

|

|

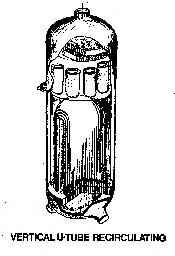

File info: source/19.jpg (size: 494 K)

Description: This Westinghouse design with an internal economizer had an incorrectly designed baffle arrangement at the inlet to the economizer section that caused major fretting problems. The design was withdrawn from the market.

Source: [DYKE2005]

|

|

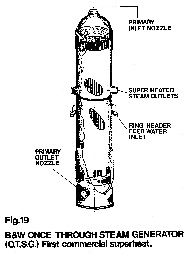

File info: source/20.jpg (size: 432 K)

Description: BW (Barberton Ohio) Once Through Steam Generator with internal economizer. BW-USA received a complete description of Canada’s internal economizer with reference to check the 'between tube' velocities at the inlet to the heating surface to avoid fretting, as noted in the technical literature for feedwater heaters (Westinghouse failed to do this). These boilers were very expensive to build.

Source: [DYKE2005]

|

|

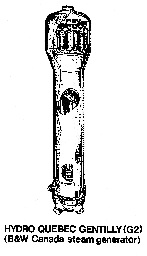

File info: source/21.jpg (size: 465 K)

Description: BW Once Through Steam Generator with superheat, the first (and only) commercial superheat SG. No internal economizer. This unit turned out to be very expensive. The OTSG also eliminated the use of cyclones steam separators and an enlarged drum section. But superheat was a problem as going to dryness caused deposition of the water chemistry crud on the super heating surface. BW follwed BWC design rules for the internals.

Source: [DYKE2005]

|

|

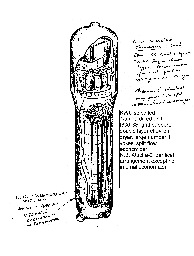

File info: source/22.jpg (size: 382 K)

Description: CANDU 6 steam generator with internal economizer.

Source: [DYKE2005]

|

|

File info: source/25.jpg (size: 801 K)

Description: Kraftwerke Union (KWU).

Source: [DYKE2005]

|

|

File info: source/28.jpg (size: 602 K)

Description: Combustion Engineering design with split flow internal economizer. Performance record is unknown.

Source: [DYKE2005]

|

|

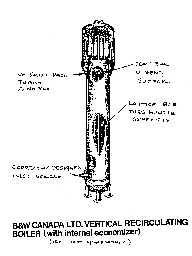

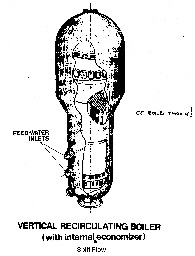

File info: source/29.jpg (size: 286 K)

Description: BWC design for Darlington: With the advent of the vertical steam drum by BW for the US Navy, and with BWC paying 1/2 the development costs, BWC used research data and added skirts to the new vertical steam cyclone spearators and included the necessary surge capacity into the base of the steam drum. This avoided the cost of a separate vessel and associated piping, thereby reducing the cost of the total system.

Source: [DYKE2005]

|

|

File info: source/30.jpg (size: 566 K)

Description: Westinghouse design with no internal economizer.

Source: [DYKE2005]

|

|

File info: source/34.jpg (size: 493 K)

Description: Experimental design, probably never built. This boiler has a by-pass lane to dry out the steam-water mixture, giving superheat and, thus, dry steam to the turbine.

Source: [DYKE2005]

|

|

File info: source/35.jpg (size: 346 K)

Description: Bruce A long drum design by AECL for surge capacity, with separate preheaters. This design experienced 'drum humping' problems causing undue stress in the T section (drum - boiler interface). The separate preheaters also experienced premature rupture disc failures that were solved by relocating the feedwater valves.

Source: [DYKE2005]

|

|

File info: source/37.jpg (size: 816 K)

Description: A collage of all Candu boilers designs.

Source: [DYKE2005]

|

|

File info: source/38.jpg (size: 730 K)

Description: A collage. Also rendered as a framed wall poster, to be donated to McMaster University.

Source: [DYKE2005]

|

|

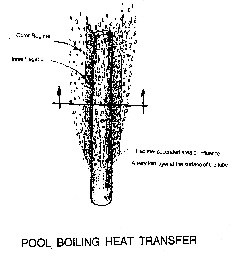

File info: source/44.jpg (size: 373 K)

Description: This sketch was drawn after video tapes were taken of boiling water in a bottle.

Source: [DYKE2005]

|